OUR TECHNOLOGY

OUR PROCESS

Research & Development Assembly Department

Markings are made on the selected stones to ensure accurate measurements are delivered throughout the process.

Bridge Cutting Department

Selected stone slabs are cut according to its preferred customised shape and size.

Edging Process Department - 45° cutting machine

A machine that provides the aesthetic cuts to stones, a 45degree angle is usually needed for edges or combination in design pieces.

Wet Polishing Department

Wet polishing is carried out by hand on stones to give it shine and luster.

Dry Polishing Department

Dry polishing is carried out to smoothen sharp edges and create seamless curves.

Assembly Department

Parts of shaped stones are put together to form a masterpiece.

Buffing & Grinding Department

Another step carried out to ensure that each stone delivered is smooth and flawless.

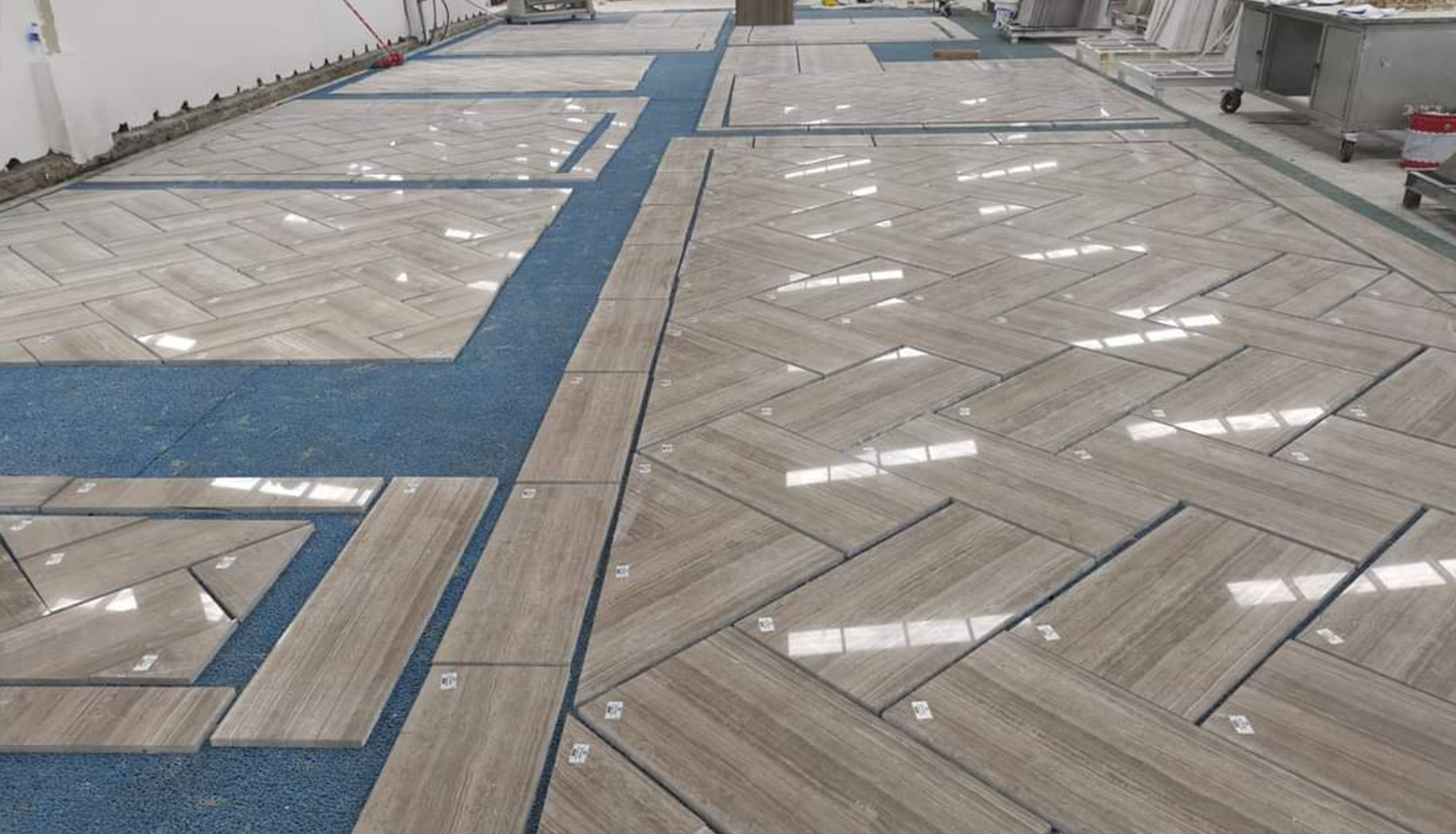

DRY LAY SERVICE

A service that allows customers to have a preview of the stones being laid out in the design specified before the actual laying of the stones.

Order Delivery Station/ Loading & Unloading Station

Raw materials that arrive and finished products are placed at this station for processing.